Projects Completed by the Gulf Process Gases Team (Process Gas, Hydrogen, Oxygen, Natural Gas and Syngas)

5.5 MM SCFD SMR H2 Generation Plant

Design & Engineering of 5.5 MM SCFD onsite H2 generation plant for reliable, low-cost supply of 99.99% pure H2 for a new hydroprocessing client (2019)

10 MM SCFD Natural Gas / (N2) Nitrogen Rejection VPSA Plant

4-bed Vacuum PSA for the removal of high N2 / nitrogen content in client’s natural gas gathering system in order to meet pipeline specs for inert gas content.

4.2 MM SCFD SMR H2 Generation Plant

Operations, Training, Technical Support by GPG at a 4.2 MMSCFD H2 plant in support of the supply of reliable H2 to client’s renewable diesel hydro-processing units.

HYCO GTL H2-CO Pilot-Scale Membrane Unit with Mass Flow & Process Control System

Custom Engineered H2 / CO mini-membrane unit for client’s GTL pilot plant, designed and operated to control and adjust the H2:CO ratio for FT reactor applications.

1.0 MM SCFD SMR H2 Plant Refurbishment Project

GPG fully refurbished a used 1 MMSCFD H2 plant along with its relocation and re-installation at a renewable fuels client.

6,000 SCFH SMR H2 Generation Units

H2Gen unit Installation of mini-SMR’s for the supply of high purity (99.999%) H2 gas, replacing low-purity H2 that was being produced by Ammonia cracking.

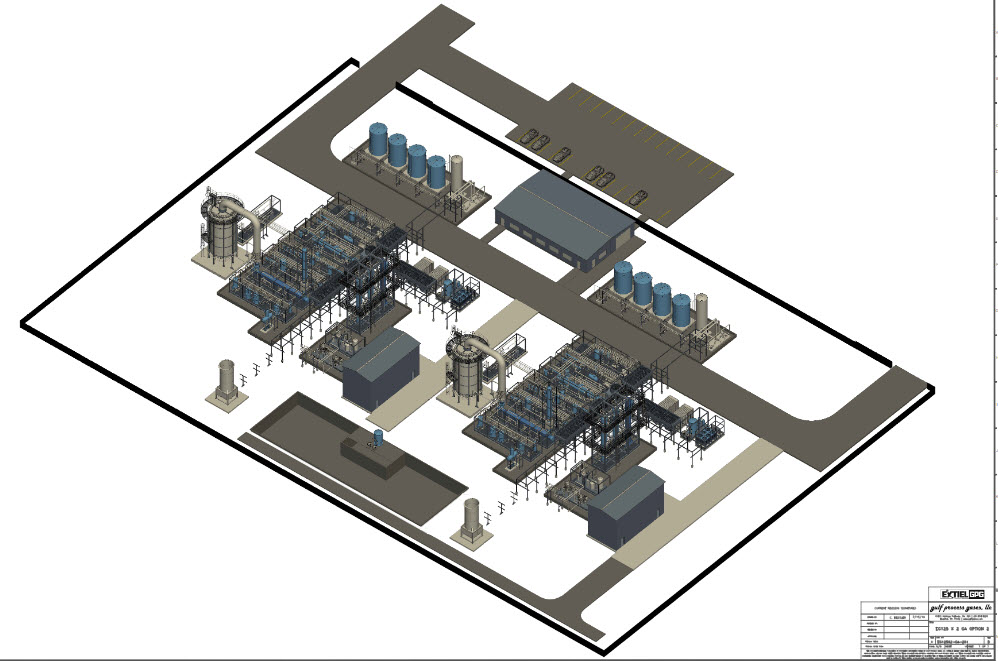

GAS TO CHEMICALS PROCESS PLANT

GPG designed and completed FEED engineering for a Specialty Performance Gas-to-Chemicals plant that will be constructed for client in 2019 / 2020. GPG built and validated the process simulation model, plus conducted catalyst selections, testing and verification runs.

H2 Storage Units

GPG completed an onsite, high-pressure H2 storage project for a unique client location. GPG provides clients with DOT or ASME approved high pressure H2 storage units. Pressures are available from 250 bar up to 700 bar (~10,000 psig) and capacities from 20,000 scf of up to 500,000 scf per unit.

10,000 SCFH H2 Generation Unit with H2 Buffer Tank

H2Gen unit installation of a modularilzed onsite H2 generation unit to replace more expensive trucked-in liquid H2 supply at a metals processing client.

115 kg/day H2 Fueling Station

H2Gen unit installation of a 115 kg/day 99.999% purity mini-SMR for a California H2 fueling station client.

1.5 MM SCFD H2 Recovery & Recycle Membrane Module

1.5 MM SCFD GPG membrane unit custom designed and engineered for GPG client’s recovery and repurification of H2 gas for recycling to hydrotreating units.

115 kg/day H2 Fueling Station

H2Gen unit installation of a 115 kg/day 99.999% purity mini-SMR for a Florida H2 fueling station client.

115 kg/day H2 Fueling Station

H2Gen unit installation of a 115 kg/day 99.999% purity mini-SMR for a California H2 fueling station client.

Natural Gas / Process Gas Desulfurization Module

Sulfur process module for the removal of mercaptans and H2S prior to GPG client’s catalytic reactor process.

1.0 MM SCFD SMR H2 Generation Plant

H2Gen unit installation of a 1.0 MM SCFD H2 production plant to supply a special metals processing client.

1.2 MM SCFD High Pressure H2 Compressor

Configuration and Procurement of cost-effective high pressure H2 compressor for GPG fuels hydroprocessing client. Installation included VFD motor controller for energy savings gas compression.

1.2 MM SCFD H2 PSA Valve & Controls Skid

GPG H2 PSA for a hydrotreating client’s recycle gas recovery and re-purification application.

1.0 MM SCFD SMR H2 Plant

Installed 1 MMSCFD H2 Plant at new re-location site for hydrotreating renewable fuels.

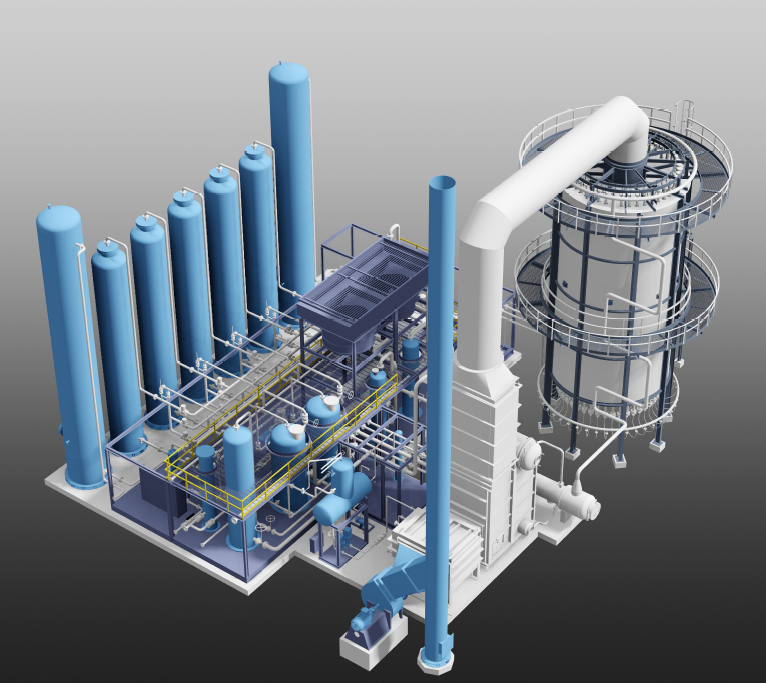

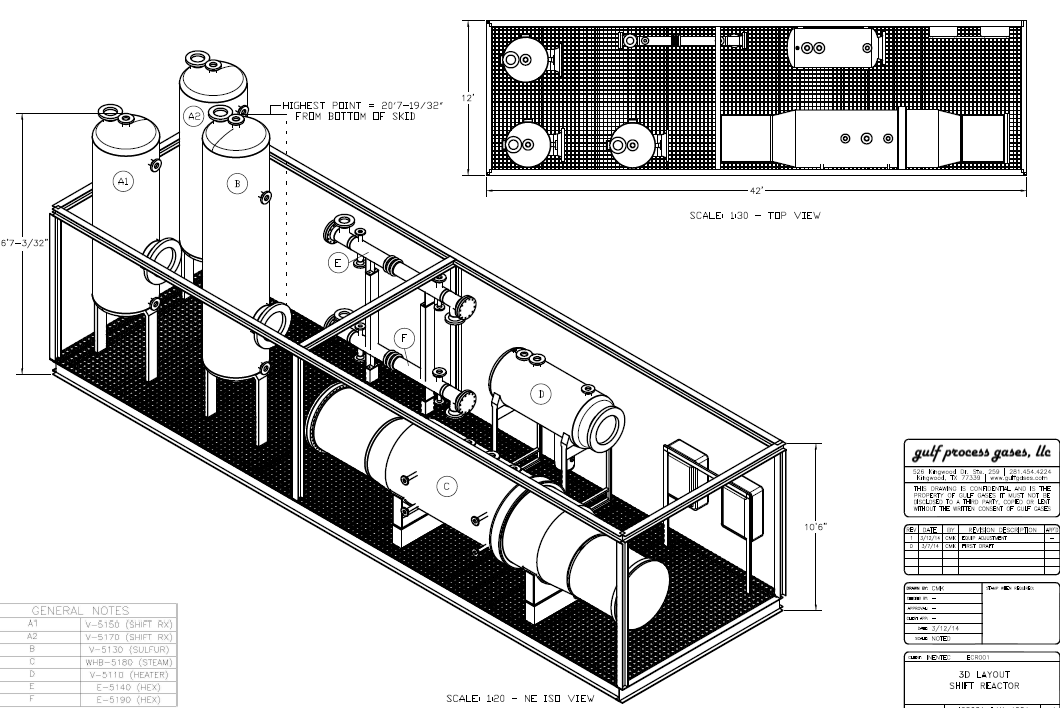

2 MM SCFD High Temperature Shift Reactor

GPG custom designed and engineered HTS / high temperature shift module to convert carbon mononoxide / CO rich vent gas to additional H2 product gas for client.

510 TPD Oxygen / Air Separation Plant

GPG performed detailed design, engineering & operations assessment for the upgrade and optimization of clients 510 TPD Cryogenic Oxygen Plant.